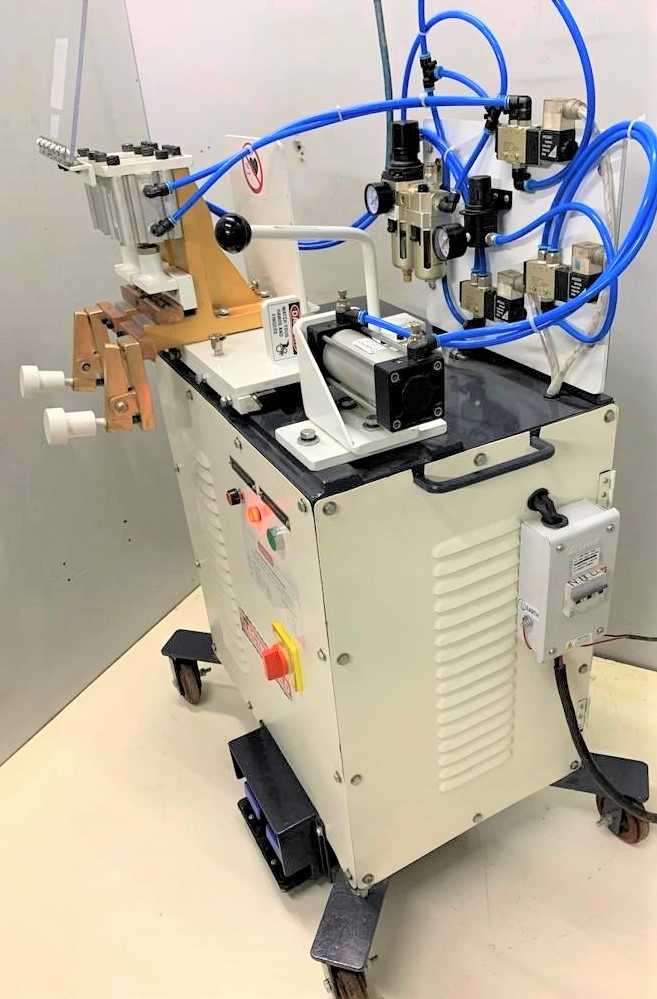

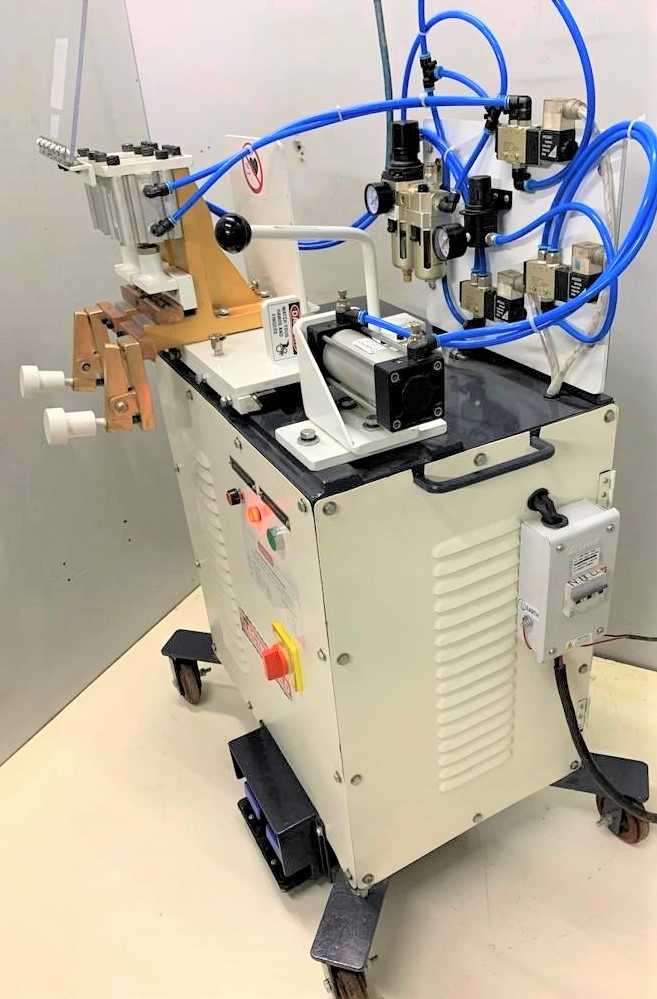

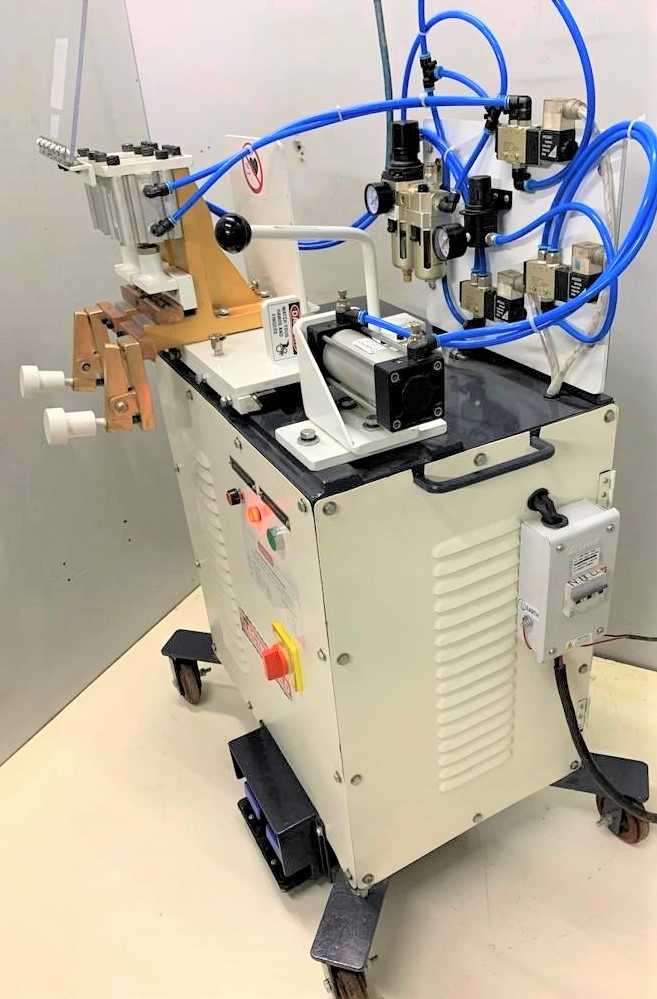

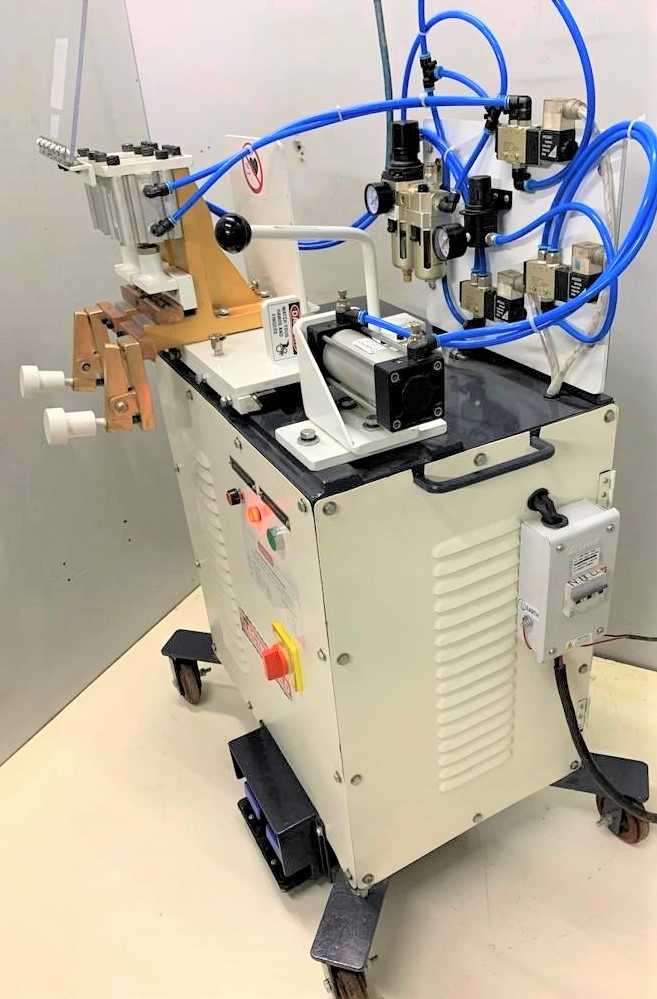

Electroweld Pneumatically Operated Rod Butt Welder 100KVA (RBW-100PN)

Video 1- Electroweld Pneumatic Rod Butt Welder 20KVA - Welding MS Steel, HS Steel, Copper and Aluminum Rods-Instructional/Operational Video

Video 2- Electroweld Pneumatic Rod Butt Welder 100KVA - Welding MS Steel, HS Steel, Copper and Aluminum Rods-Instructional/Operational Video

Video 3- Rod Butt Welding Application

Video 4- Ring Butt Welding Application

Video 5- Small Ring Butt Welding Application

Video 6- Gasket Ring Butt Welding Application

Video 7- Rod Butt Welding Instructional and Operational Video-150 KVA Model

Video 8- Rod Butt Welding Instructional and Operational Video-40 KVA Model

Electroweld Pneumatic Rod Butt Welder 20KVA - Welding MS Steel, HS Steel, Copper and Aluminum Rods-Instructional/Operational Video

Electroweld Pneumatic Rod Butt Welder 100KVA - Welding MS Steel, HS Steel, Copper and Aluminum Rods-Instructional/Operational Video

Operational Video for the Electroweld Pneumatically Operated Rod Butt Welder - Welding Rods

Operational Video for the Electroweld Pneumatically Operated Rod Butt Welder - Welding Rods

Operational Video for the Electroweld Pneumatically Operated Ring and Gasket Butt Welder

Operational Video for the Electroweld Pneumatically Operated Small Ring Butt Welder

Operational Video for the Electroweld Pneumatically Operated Gasket Ring Butt Welder

Operational Video for the Electroweld Pneumatically Operated Large M.S Ring Butt Welder

Operational Video for the Electroweld Pneumatically Operated Large M.S Ring Butt Welder

Operational Video for the Electroweld Pneumatically Operated Butt Welder - Welding Cycle Rims

Operational Video for the Electroweld Pneumatically Operated Rod Butt Welder - Welding Drill Bit to Shank(Authorized Dealer Video)

Operational Video for the Electroweld Pneumatically Operated Rod Butt Welder - 40 KVA Model(Authorized Dealer Video)

What is Butt-Welding or Upset Welding?

Butt-welding is a technique where two metal ends are connected with no overlap, forming a near seamless merger. To do so, the two ends are heated by passing an electric current through the weld interface. The interface causes heating due to resistance to the current. Heating continues until the metal reaches a plastic-like state. The ends (or butts) are then pressed together, where they form a knot or upset. The knot or upset is then ground down to a smooth finish. This technique is great for creating closed-loop steel rings or welding rods. Butt-welding is sometimes used interchangeably with Upset Welding. As we can see both of them are the exact same process with just a difference in the name.

Annealing-Post Weld Heat Treatment (PWHT):

Heat-treatment post welding involves, changing the properties of metals such as carbon steel or alloy steel by processes involving heating. It is used to harden, soften, or modify other properties of materials that have different crystal structures at low and high temperatures. The type of transformation depends on the temperature that the material is heated to, how fast it is heated, how long it is kept heated, what temperature it is first cooled to, and how fast it is cooled. For example, quenching hardens steel by heating it to high temperatures and then quickly immersing it in room temperature oil, water, or salt brine to prevent carbon atoms from moving through the crystal structure and forming carbides, which soften the metal. The two main approaches to softening a metal (to restore its ductility) are annealing, in which its temperature is slowly raised, held for some time, and slowly cooled, and tempering, in which it is slowly heated in an oil bath and held for some hours.Heat treatment following welding may be carried out for one or more of three fundamental reasons:

-To achieve dimensional stability in order to maintain tolerances during machining operations.

-To produce specific metallurgical structures in order to achieve the required mechanical properties.

-To reduce the risk of in-service problems such as stress corrosion or brittle fracture by reducing the residual stress in the welded component.

What is Annealing:

Annealing is a heat treatment process which alters the microstructure of a material to change its mechanical or electrical properties. Typically, in steels, annealing is used to reduce hardness, increase ductility and help eliminate internal stresses. This consists of heating a metal to a high temperature, where recrystallisation and/or a phase transformation take place, and then cooling slowly. This is often carried out to soften the metal after it has been hardened, for example by cold working; a full anneal giving the very softest of microstructures. It also results in a reduction in both the yield and the tensile strength and, in the case of ferritic steels, usually a reduction in toughness.One of the main applications of annealing is reversing the effects of work hardening. Besides steels, other metals may also benefit from annealing such as copper, aluminium and brass. For steels, subcritical annealing takes place at 540°C - 640°C (1000°F – 1200°F), so there is no crystal structure change. Intermediate annealing is carried out at 640°C - 760°C (1200°F – 1400°F), so there is some transformation to austenite and full annealing involves completely austenitizing the work at 815°C - 925°C (1500°F – 1700°F).

Why is Stress Relief required post-welding:

Welding involves the deposition of molten metal between two essentially cold parent metal faces. As the joint cools the weld metal contracts but is restrained by the cold metal on either side; the residual stress in the joint therefore increases as the temperature falls. To reduce this high level of residual stress, the component is reheated to a sufficiently high temperature. As the temperature is increased the proof strength falls, allowing deformation to occur and residual stress to decrease until an acceptable level is reached. The component would be held at this temperature (soaked) for a period of time until a stable condition is reached and then cooled back to room temperature. The residual stress remaining in the joint is equal to the proof strength at the soak temperature.

How does Stress Relief work via Post Weld Heat Treatment?

Stress relieving is a technique to remove or reduce the internal stresses in a metal. These stresses may be caused by a number of reasons, ranging from cold working to non-uniform cooling after forging. Stress relieving is usually accomplished by heating a metal below the lower critical temperature and then cooling uniformly. It relies upon the fact that, as the temperature of the metal is raised, the yield strength decreases, allowing the residual stresses to be redistributed by creep of the weld and parent metal. The high residual stresses locked into a welded joint may cause deformation outside acceptable dimensions to occur when the item is machined or when it enters service. High residual stresses in carbon and low alloy steels can increase the risk of brittle fracture by providing a driving force for crack propagation.

Listed price includes supplier paid shipping via CIF – Cost, insurance, and freight (named port of destination).

Any additional brokerage, customs, and duty fees associated with international shipments are the customer's responsibility and are not included

All return shipments including international return shipments would be at the cost of the buyer

We accept Paypal

The Warranty Information for ELECTROWELD INDUSTRIES products is available HERE

The TERMS & CONDITIONS for ELECTROWELD INDUSTRIES products is available HERE

Standard Incoterms Information on included shipping to destination port via CIF (Cost, insurance, and freight) is available HERE

- The machines will be shipped 2-3 weeks after clearance of payment.

- Shipping times may vary depending on any custom modifications and complexity of the request.

- Shipping times may vary depending on larger than 2 Qty of machines ordered in a shipment

- Additional spares and consumables can be ordered separately to be shipped together with the machines

- Standard one year warranty with the faulty machine shipped to factory and back to buyer after repairs both at buyers expense

- Cost, insurance, and freight (CIF) is an expense paid by a seller to cover the costs, insurance, and freight of a buyer's order while it is in transit. The goods are exported to a port named in the sales contract. Until the goods are fully loaded onto a transport ship, the seller bears the costs of any loss or damage to the product. Further, if the product requires additional customs duties, export paperwork, or inspections or rerouting, the seller must cover these expenses. Once the freight loads, the buyer becomes responsible for all other costs.

+

Frequently Asked Questions (FAQ's) :

For Price Quote Requests please send an email with your welding machine requirements to sales@electroweld.com

or

Submit the Price Quote Request via the following link:

For direct help with selecting the right machine for your welding requirements and application you can also Book an Online Zoom Meeting with our Electroweld Sales Engineers or Call Us directly at the phone numbers listed below.

Electroweld Industries

5, Hira Compound, R.C Marg, Chembur, Mumbai, INDIA - 400074

Call (India Office): +91 222 522 6180, +91-9702579330

Mobile/Whatsapp: +91-9820160332

Call (USA/Mexico Sales): +1 (214)-636-3048

Email: sales@electroweld.com

Drop us a line and we’ll get back to you as soon as possible

An online order can be placed directly on the Electroweld Online Store by adding your Machine to the Cart and completing the order forms during the checkout process.

Note: At the end of the checkout process you will have the option of completing the payment via Paypal or you can choose to place the online order without the payment details. We will contact you separately on receiving the online order and discuss the payment method offline.

or

Purchase Order can also be directly submitted via sales@electroweld.com or Fax: + 91-22-25272731.

For ordering parts please send an email to sales@electroweld.com with the Machine Model Number and the requested Part Name/Number (or picture of the part). We will revert back with the part pricing and order completion details.

Note: The machines will be available for shipping FOB / CIF Ex-Works , 4 weeks after clearance of payment. We can only put your order into production once the payment has been cleared.

Payments can be processed either via PAYPAL using the link: https://paypal.me/electroweld74

OR

Request Payment Instructions for Wire Transfer or Cashiers Check when submitting your purchase order by sending an email to sales@electroweld.com

- The order will ship as per our quotation post receipt and clearance of payment. Shipping times may vary depending on any customization of the machine needed for your application and any additional charges will be added to the final invoice. Please send any customization requests to sales@electroweld.com

- For International Orders the listed price includes supplier paid shipping via CIF – Cost, insurance, and freight (named port of destination). FOB or DAP quotes available on request

- Cost, insurance, and freight (CIF) is an expense paid by a seller to cover the costs, insurance, and freight of a buyer's order while it is in transit. The goods are exported to a port named in the sales contract. Until the goods are fully loaded onto a transport ship, the seller bears the costs of any loss or damage to the product. Further, if the product requires additional customs duties, export paperwork, or inspections or rerouting, the seller must cover these expenses. Once the freight loads, the buyer becomes responsible for all other costs.

- Any additional brokerage, customs, and duty fees associated with international shipments are the customer's responsibility and are not included.

FREE International Shipping to your nearest port via sea shipment (CIF-Named Port of Destination). This ensures your end cost of shipping is equivalent to buying your machine locally from a dealer in your country. Separately shipping costs for all local orders within INDIA are quoted during Invoicing

- Machines are usually ready to ship within 4-weeks of Payment Clearance. Additional time might be taken for certain complex customization requests.

- We send actual videos of operation, showing the working of your machine and welding of any sample parts as per your requirements to the email address on the invoice before shipment.

- We also ensure that the machines are crated and packed as per shipping requirements to your country of delivery.

- Tracking details will be sent out via Email or SMS when available.

- For International Orders the listed price includes supplier paid shipping via CIF – Cost, insurance, and freight (named port of destination). FOB or DAP quotes available on request

- Cost, insurance, and freight (CIF) is an expense paid by a seller to cover the costs, insurance, and freight of a buyer's order while it is in transit. The goods are exported to a port named in the sales contract. Until the goods are fully loaded onto a transport ship, the seller bears the costs of any loss or damage to the product. Further, if the product requires additional customs duties, export paperwork, or inspections or rerouting, the seller must cover these expenses. Once the freight loads, the buyer becomes responsible for all other costs.

- Any additional brokerage, customs, and duty fees associated with international shipments are the customer's responsibility and are not included.

Standard Incoterms Information on included shipping to destination port via CIF (Cost, insurance, and freight) is available HEREWARRANTY:

We take pride in the quality and reliability of our well engineered Welding Machines . Our machines come with a Standard ONE Year Parts and Labor Warranty.

EXTENDED WARRANTY:

We also provide 1YR and 2YR Extended Warranty Options for purchase, which can give you further peace of mind on your equipment purchase.

For Extended Warranty Quote Requests please send an email with your extended term requirements to sales@electroweld.com

The Warranty Information for ELECTROWELD INDUSTRIES products is available HERE

SUPPORT:

Electroweld product manuals provide technical details on installation and commissioning. We can additionally provide remote support to your engineers for successful turn-up and commissioning of your machine. We can also provide a quote for on-site service if available in your country.

Please submit a Service Request using the following link:

You can also submit your Service Requests via email to service@electroweld.com

The TERMS & CONDITIONS for purchase of ELECTROWELD INDUSTRIES products is available HERE

Electroweld Industries

5, Hira Compound, R.C Marg, Chembur, Mumbai, INDIA - 400074

Call (India Office): +91 222 522 6180, +91-9702579330

Mobile/Whatsapp: +91-9820160332

Call (USA/Mexico Sales): +1 (214)-636-3048

Email: sales@electroweld.com

Drop us a line and we’ll get back to you as soon as possible

Contact Details:

Drop us a line via email or using the Contact form below and we will help find the best solution for your Welding Applications.

Electroweld Industries

5, Hira Compound, R.C Marg

Chembur, Mumbai, INDIA - 400074

Call (India Office): +91 222 522 6180, +91-9702579330

Mobile/Whatsapp: +91-9820160332

Call (USA/Mexico Sales): +1 (214)-636-3048

Email: sales@electroweld.com

Drop us a line and we’ll get back to you as soon as possible